Testing reduces risk and improves quality as the team designs their revolutionary seaplane concept for DARPA

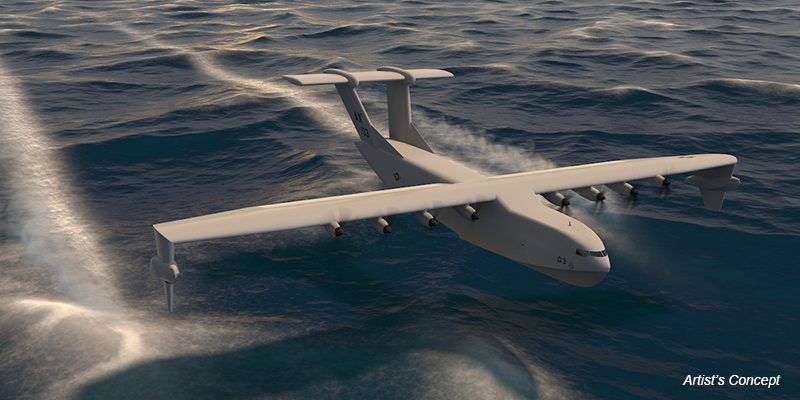

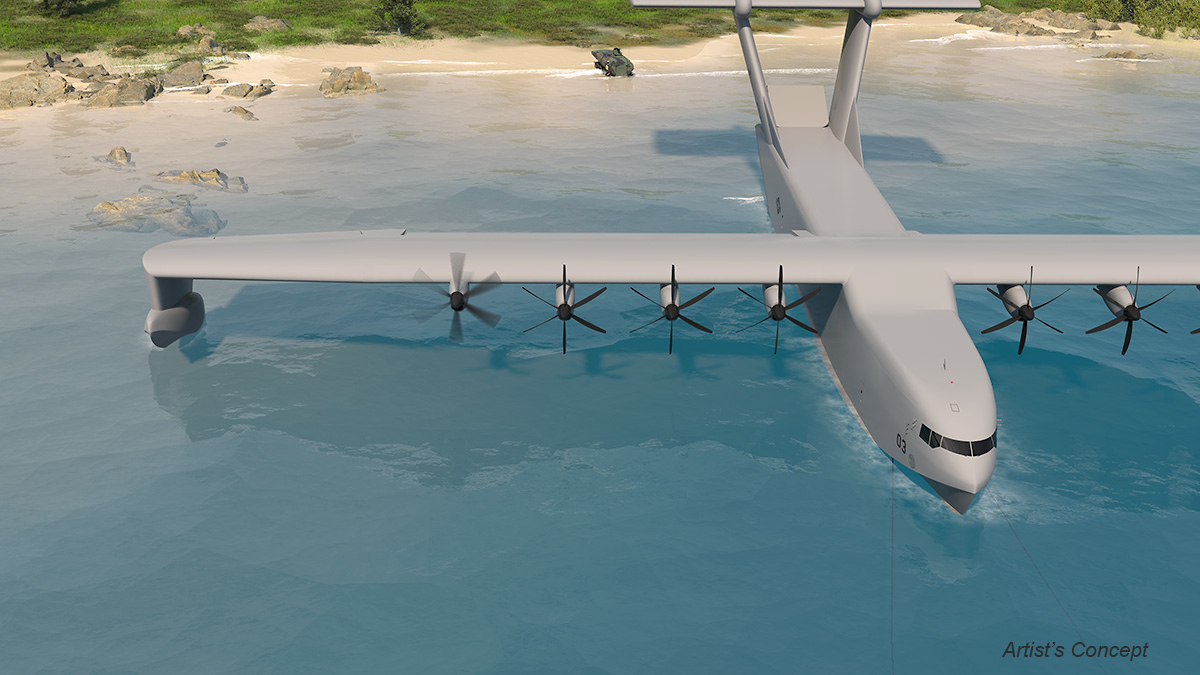

Aurora Flight Sciences, a Boeing company, is progressing through Phase 1B of the Liberty Lifter program, the Defense Advanced Research Projects Agency (DARPA) program that aims to design, build, float, and fly an affordable X-plane that demonstrates revolutionary heavy-air-lift capability from the sea. To meet this revolutionary capability, the vehicle will operate efficiently in ground effect at high sea states and demonstrate affordability using low-cost manufacturing and unique design features.

The end goal of Phase1B is preliminary design, and a major focus during the phase is testing for risk reduction. ReconCraft, an Oregon-based shipyard, is an Aurora team member providing expertise in maritime manufacturing methods. The company will build full-scale structural test articles, including a portion of the fuselage. The build and testing of structures reduces risk and ensures quality, as the team works with novel materials and unique requirements. The Aurora team also tested a scale model of the hull in the tow tank at Virginia Tech, which offers a unique capability to study the slamming of craft during landing. Upcoming testing includes flying sensors and software for wave detection and prediction, which feeds the X-plane’s advanced control system for safely flying in ground effect over high sea states.

In its latest iteration, Aurora’s design for Liberty Lifter changed from a t-tail to a pi-tail, which is more structurally efficient when accommodating an aft cargo door. Additionally, the floats were relocated from the side-sponsons to the vehicle’s wing tips, which creates a better balance between vehicle affordability and performance in ground effect.

Along with ReconCraft, the Aurora-led team includes leading naval architecture and marine engineering company Gibbs & Cox, a Leidos company. The company plays a critical role as the X-plane is, in many ways, a boat that flies. Several advisors and engineers from Aurora’s parent company, Boeing, also bring their expertise to the team. The program benefits from previous research and development by Boeing, which has a long history in seaplanes and flying boats.

“Innovations often occur at intersections. Here, it’s the intersection of our maritime and aerospace teams,” said Dan Campbell, Aurora program manager. “For example, the intersection of maritime manufacturing with aerospace structural design, or the intersection of maritime wave forecasting with aerospace controls.”

Phase 1B concludes with a preliminary design review, tentatively scheduled for January 2025. If the program progresses, flight testing would occur in 2028.

DISTRIBUTION STATEMENT A. Approved for public release. Distribution is unlimited.

ABOUT AURORA FLIGHT SCIENCES

Aurora Flight Sciences, a Boeing company, advances the future of flight by developing and applying innovations across aircraft configurations, autonomous systems, propulsion technologies, and manufacturing processes. With a passionate and agile team, Aurora delivers solutions to its customers’ toughest challenges while meeting high standards of safety and quality. Learn more at www.aurora.aero

# # #

Contact:

Carmen Smith, Aurora Flight Sciences, A Boeing Company

smith.carmen@aurora.aero